QUICK FACTS

Recent incidents indicate unexpected failures of climbing anchors under low loads and after only some months or years in place. These failures occurring mostly on stainless (!) steel anchors are due to environmental degradation, i.e. corrosion and more specifically stress corrosion cracking (SCC).

- In worst cases, anchors can break under only a few tens of kilograms – less than the climber weight

- Usually along seasides but can be some km away from the coast

- Corrosion is not always visible. Could be invisible cracks

- Stress corrosion cracking, which is the most virulent, could initiate cracks very rapidly after anchor installation. Within some weeks maybe, a few months for sure.

- All stainless steels, even the 316L grade, are concerned

- The UIAA Safety Commission is working on finding anchors with material suitable for these environments

- All material in place shall be considered as potentially affected

MOST CRITICAL FACTORS

- “Moderate” relative humidity location (very dry is OK, and very humid also, in between is a problem);

- Area NOT washed by rain (even washed by the sea can be OK!!);

- Temperature is not critical, SCC can occur at 20°C, but higher temperatures are worse;

- Rock types: limestone/dolomite is generally worse than sandstone or granite (karst is the worst case)

Stress corrosion cracking (SCC) has been confirmed as the cause of a number of recent climbing anchor (bolt) failures and is further suspected in many more incidents.

Small differences in microclimate can lead to SCC degradation for some bolts, while other bolts on the same climb are unaffected. SCC is associated with seaside climbing but can also occur in inland areas where corrosive elements are present, either naturally occurring in the rock itself or deposited inland by sea breezes.

WHAT YOU SHOULD KNOW AS A CLIMBER

Only destructive testing can confirm the presence/absence of SCC on installed anchors. It is not possible to visually assess or even to casually test (like to pull on them) the effective strength of the anchors in place. Even anchors that have been installed in recent months and/or look brand new could be compromised by SCC or some forms of corrosion.

Tests done by a Petzl France on all bolts of an example cliff show that 20% of the installed anchors had a strength between1 and 5 kN and thus would barely sustain body weight, let alone the mildest of fall arrests. Such conditions lead to incidents like the one that occurred in Sicily: during rappelling, the lower bolt of the belay broke under only the body weight of the climber (65 kg); fortunately the upper bolt held and the three climbers were unharmed.

Recommendations for climbers

When planning a trip

- Consider SCC when assessing the risk of climbing at a proposed climbing destination

- Check with local climbers and/or climbing organizations regarding the prevalence of SCC and the corrosion resistance of local bolts

- Be prepared for the presence of SCC, especially at hot, seaside, limestone/dolomitic destinations (Karst is the most aggressive rock)

When climbing

- Consider SCC when assessing the risk of climbing a given route.

- Belay/lower from redundant, multi-bolt anchors

- Back up bolts and belay/rappel stances with nuts, camming devices, trees, and/or threaded hourglasses

- Be prepared to abandon projects with suspect bolts

In the event of bolt failure (once the climbers are safe and possible injuries have been attended to)

- Collect the failed anchor parts; avoid disturbing the failure surface or trying to piece together the failed anchor.

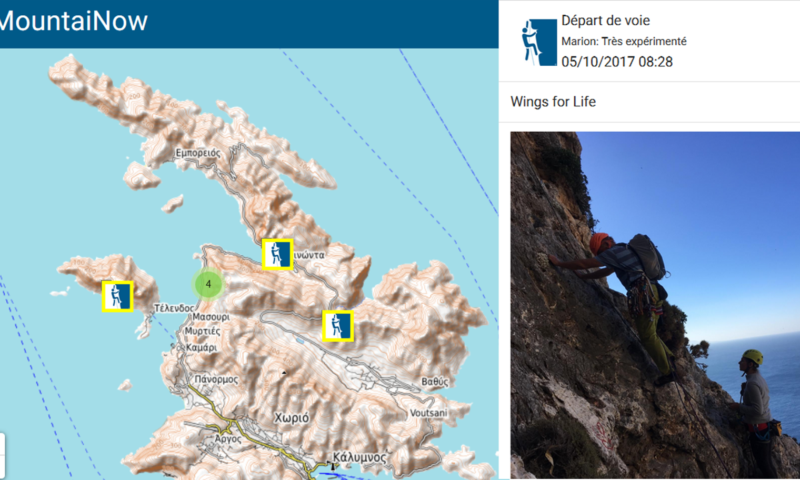

- Inform the local climbing community. Post an observation on MountaiNow (via app or web) to geo-localize the failure and inform the whole community in real-time.

- Contact the UIAA and make the failed anchor parts available to the UIAA or one of its national federations for analysis.

Drawn from UIAA “Watch you anchor! Corrosion and stress corrosion cracking failure of climbing anchors”; see full article here. Copyrights – except for images – INTERNATIONAL CLIMBING AND MOUNTAINEERING FEDERATION (UIAA)